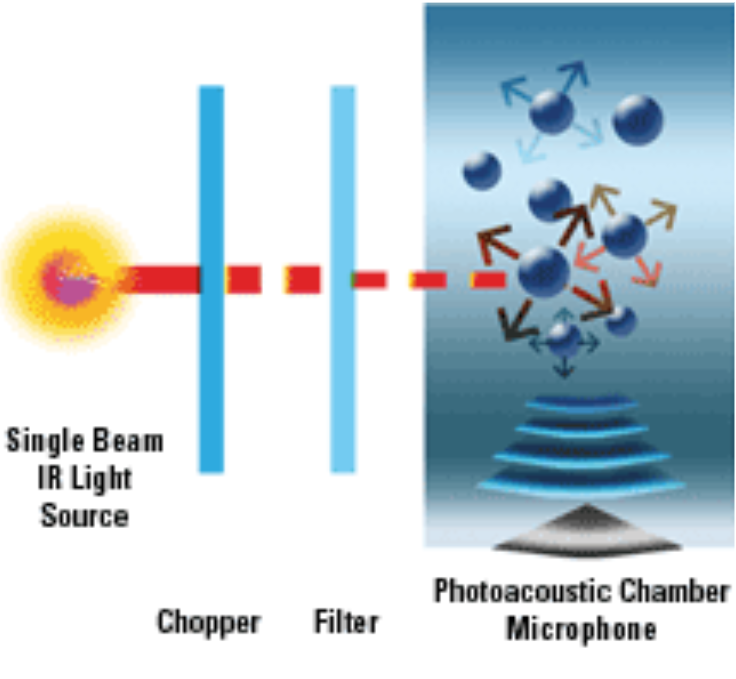

Photoacoustic IR Ammonia Gas Detection

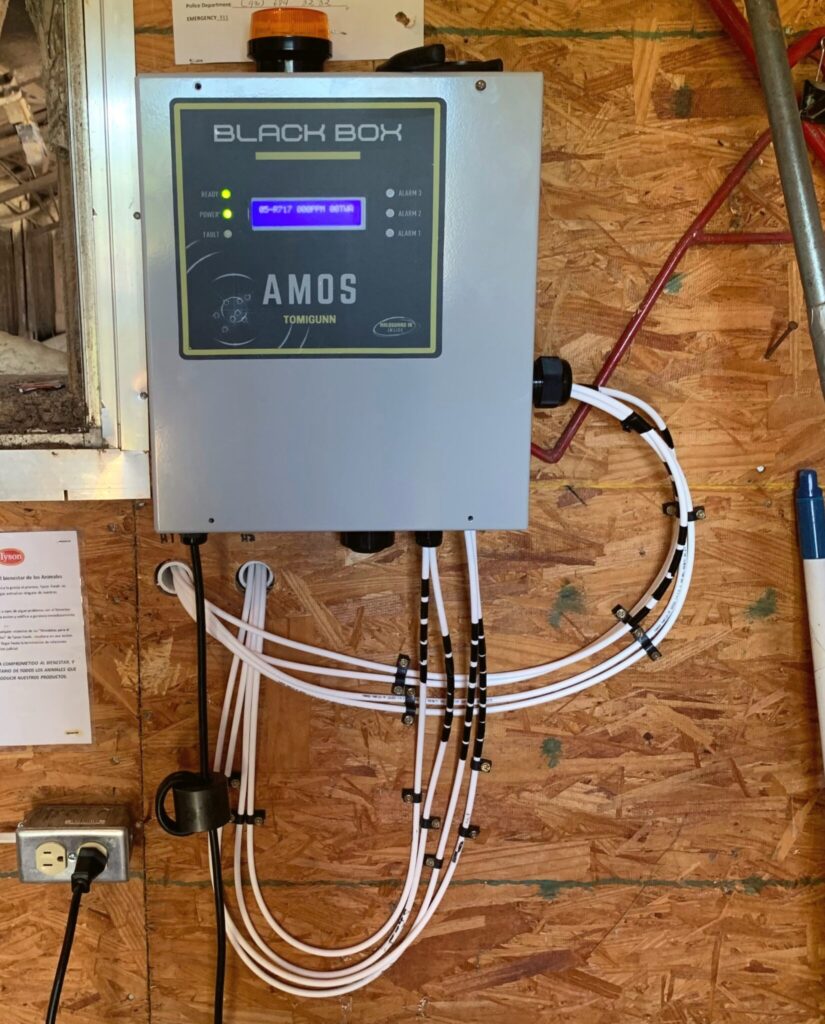

BLACK BOX by TOMIGUNN is an ammonia gas detection sensor that uses photoacoustic infrared technology to give you accurate ammonia-level data down to 1 ppm.

BLACK BOX does not need constant calibration, and because the ammonia detection takes place in the control room and not in the house, the instrument is protected from the corrosive effect exposure to ammonia vapor can cause.

The ammonia sniffer collects an air sample at a given location and returns it to the photoacoustic analyzer in the BLACK BOX control panel. Sniffer location points are placed 10 inches from the litter at bird level.

GENERAL DESCRIPTION

Bird-Level Measurements

BLACK BOX collects air quality samples at predetermined locations. Location points are placed 10 inches from the litter at bird level. A vacuum transports the air sample to the infrared sensing technology located in the control room, where the sample data is analyzed for accurate ammonia concentration levels.

BLACK BOX ammonia sensor includes up to eight ammonia collection points strategically placed in the poultry house. BLACK BOX is customizable for up to three pre-set warnings: alarm, alert and critical.

Add-on Sensor Capabilities

With the BLACK BOX modular design, you can add other sensors such as oxygen and carbon dioxide. Inside the BLACK BOX controller is the capability to initiate various pieces of equipment such as lighting, fans, and heating.

BLACK BOX Uses Photoacoustic Infrared Sensing Technology, So There Is No Need For Comparative Sampling To Derive The Baseline Zero Reading, No Saturation Of The Sample Cell Even With Prolonged High PPM Readings, And No Cross-Contamination From Other Vapors That May Be Present.

UNIT SPECS

- Electrical Supply: 100-240VAC, 50-60 Hz

- Replaceable Fuse: 3A / 240V; fast-acting

- Output Signal: Std: 7 x 10A dry contact relays; Opt: RS-232; Opt: 0-5, 10VDC or 4-20mA

- Sensitivity: 1 ppm

- Display Resolution: 1 ppm Full Scale (1 to 1000 ppm)

- Response Time: <1 minute

- Clearing Time: <3 minutes

- Measuring Range: 0 – 1000 ppm

- Operating Conditions: 32 degrees F to 120 degrees F non-condensing

- Enclosure: Std: NEMA 12 (weight 24 lbs); Opt: NEMA 4 (weight 28 lbs)

- Weight: NEMA-12: 23 lbs. (10.4 kg.); NEMA-4: 28 lbs. (12.7 kg.)

- Dimensions: NEMA-12: 12” W x 14” H x 4.5” D (30.48 cm x 35.56 cm x 11.43 cm); NEMA-4: 12” W x 14” H x 6” D (30.48 cm x 35.56 cm x 15.24 cm)

- Packing Dimensions: 20″ x 11″ x 23″

- Packing Weight: 26 lbs NEMA-12, 30 lbs NEMA-4

- Electrical Safety: Conforms to UL/CSA/EU 61010-1

- EMC Compatibility: Conforms to FCC Part 15 B, ICES-003: Issue 5, ANSI C63.4:2009; EN 61326-1